Engineering

Precision Engineering for Offshore Challenges

DDI has designed and manufactured a wide range of Oil & Gas Products. Our Core team is Highly experienced, flexible and have kept team integrity continuous for 15+ years.

Backed by decades of experience and a fully equipped Houston facility, we build with precision so you can operate with peace of mind.

Our facility opened in 2005 (Expanded in 2016), combining precision-machined parts with custom welding fabrication.

Customized to your needs

- Pressure Testing, Pull Testing, and Testing Arrangement Design

- FEA Analysis, 3D Modeling and Event simulation

- Drafting Support for Autodesk Inventor and Autocade

Detail Design can meet your special requirements

Testing

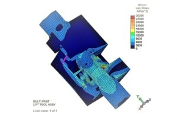

FEA ANALYSIS

DRAFTING SUPPORT

Testing

Our testing services are available on a turnkey basis, delivering end-to-end validation you can trust—from setup through final documentation.

Drafting Support

Turnkey drafting support is available using AutoCAD and Autodesk Inventor, meeting ASME Y14.5 and ASME Y14 standards.

Finite Element Analysis (FEA)

Our custom-designed equipment is fully engineered using the latest computational tools including Autodesk Inventor, Autocad and Linear/Non-Linear FEA Simulation.

Our Design Reports and Data Books are routinely approved by certifying agencies such as DNV, ABS and BV.

- Mechanical Event Simulation

- Linear and Non Linear Event Simulation

- 2D Autocad & Inventor 3D Parametric Modeling

Guided by our professional engineering staff, our fabrication, assembly and test personnel are experts in custom solutions for subsea, surface, and mobile:

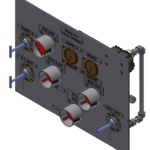

- ROV Intervention Tooling, Hot Stabs, Valves, and Panels

- TLP Tendon Buoy Systems

- Heavy Lift Appliances

- Subsea Accumulator Skids

- Choke/Kill Connectors and Quick Disconnect Systems

- Hose Reels

Custom Design

Truck Mounted System

Custom Engineered Mobile

Solutions for Oilfield Operations

Detail Design designs and fabricates custom truck-mounted trailer systems built to support demanding oilfield applications. These specialized units are engineered to safely transport and meter corrosive chemicals directly into well fracturing streams, delivering reliable performance in harsh operating environments.

Working in close collaboration with our clients, we define trailer configurations, perform detailed engineering and analysis, and fabricate prototype systems to meet precise operational requirements. Our modular design approach allows each system to be easily reconfigured as project needs evolve—providing flexibility, efficiency, and long-term value.

Equipment Walker

Each “Foot” can support and move 200-tons, inchworm style. A set of four is typically used to reposition heavy equipment. The Walker is bolted to the equipment and the vertical cylinder is extended to lift the equipment. Once lifted, the equipment is moved laterally with a 2-ft stroke in any direction. After the step, the Walker cylinders are retracted in preparation for the next step.

LAR Systems

Custom designed for DDI’s customer for his Autonomous Underwater Vehicle (AUV) and vessel, this Launch and Recovery System (LARS) is hydraulically operated using a wireless remote control. Power is provided by a 60-hp HPU.

The control system has triple redundancy for reliability. Features are provided to “gently” recover the floating vehicle.

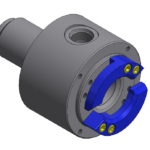

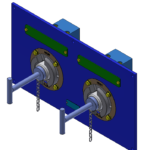

10,000 Psi Actuator

DDI has designed and manufactured high pressure actuators for the offshore oil industry. Standard configurations can be adapted to properly fit onto your equipment.

Detail Design can meet your special requirements.

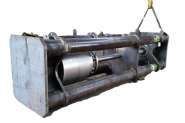

Long Life Cylinders

Detail Design Inc. manufactures hydraulic cylinders specifically designed to withstand the rigors of the subsea operating environment. The cylinders are custom designed to suit specific applications and are designed to deliver the reliability that a subsea application demands.

DDI’s cylinders are manufactured with 316 SS barrels and heads and NITRONIC 50 pistons and rods. End configurations are designed to interface with the actuated equipment. Small bore (up to 3″ bore) low and medium pressure (up to 3000 psi) utilizes tie rod design, while higher pressure and larger bores utilize threaded or bolted head designs.

DDI’s cylinders utilize nylon wear rings to eliminate metal to metal contact between moving parts, minimizing the danger of galling and ruining the seal surfaces. The piston features double acting seals to ensure a positive seal to the cylinder in both directions. All joints, static and dynamic, exposed to sea water feature a seal to prevent sea water intrusion into the cylinder. DDI’s blind use cylinders (applications where the piston rod or moving equipment cannot be seen) even feature a tell-tale that allows a visual indication to an ROV of the piston position.

Motion Compensation

Air-over-oil constant-tensioning systems are used throughout the offshore industry to maintain tension on risers and guidelines. Tensioners work on the air spring principle. This unit was custom-designed to tension a small diameter drill string being deployed from a work boat.

The system applied a variable tension up to 20,000-lbs on the hook. Not shown is a suite of standard gas bottles which were manifolded together to create the system reservoir.

Safety features of the high pressure air system include safety wires inside large diameter pneumatic hoses, excess flow velocity shut-offs, and the use of water-based lubricating fluids.

The system was configured for easy air freight shipping.